MK Foil Stamping Machine is modern printing equipment that has automated feeding and waste removal systems to carry out decorative printing tasks quickly and accurately. It involves foil stamping shiny metallic and/or colored finishes on packaging, cards, books, and other printed paper supports, making them more attractive to viewers. The automated mechanisms of this machine enhance efficiency by eliminating manual work, thus creating smooth operation and quality at an equivalent level.

Automated Feeding System

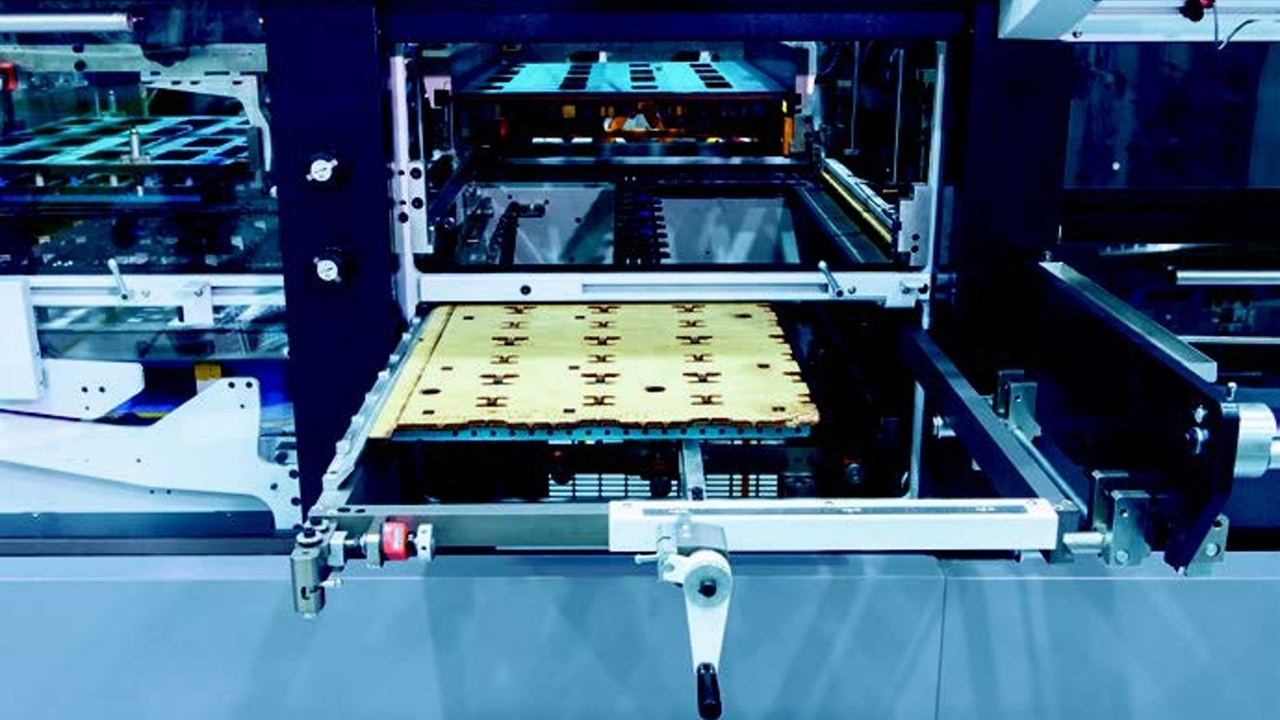

The automated feeding system is one of the significant characteristics of the MK Foil Stamping Machine. This system feeds single sheets or materials into the machine one at a time, taking out several sheets or materials at a time. This operation is fast and consistent, assisting in maintaining the continuous flow of production with minimal manipulation. The automated feeding system frees the operators from the task of loading them one sheet at a time, thereby saving time, and allows for permanent production to be maintained at an even speed. It also reduces the chances of error, such as feeding uneven sheets or misaligned sheets.

Smooth and Accurate Foil Stamping

The machine applies foil stamping through controlled heat and pressure. Once a sheet enters the stamping area, the foil is stamped onto a surface according to the design. Such a process will make every stamped detail sharp, bright, and consistent. The accuracy of the stamping process ensures that it handles even intricate designs with great precision. The machine produces readable and credible results, whether it is a miniature script or complex patterns.

Waste Removal System

Another essential feature is the automated waste removal system. During foil stamping, excess foil or material can be left behind around the design. The system of waste removal eliminates these unwanted details without necessitating any manual cleaning. This maintains the working area clean, and waste material does not mix with the stamping process. The machine also reduces production time and downtime between jobs by automatically removing waste.

Benefits of Combining Both Systems

The MK Foil Stamping Machine is highly efficient due to automated feeding as well as waste removal. The feeding system maintains the equipment with materials, and the waste removal system makes every stamped product emerge clean and free of waste. Both of them minimize the need for manual work, accelerate the process, and enable maintaining a certain level of quality in the resulting work. This combination also lowers the chances of production delays caused by sheet handling or waste buildup.

Applications in Different Industries

The MK Foil Stamping Machine can be used in a variety of industries. Packaging companies often use it to create attractive product boxes. It finds use in the production of greeting cards, invitations, and stationery, which have shiny decorative finishes from printing firms. It is a tool that book publishers can utilize in printing metallic lettering or designs on covers. The machine can be applied in any business that considers appealing and professional-looking printed materials.

Conclusion

The MK foil stamping machine features a built-in automatic feeding and waste disposal system, providing a viable solution for creating high-quality, well-stamped foil material without the need for repetitive actions; instead, it operates in a constant rhythm. Its feeding system promises ease of handling the material, and its waste removal system guarantees a clean and efficient production. With the confluence of these features, this machine provides a steady output and can save a treasured amount of time, which is why it is a good option to consider in numerous printing and packaging processes.